EnPower, Inc. is celebrating National Battery Day by showcasing the company's significant upcoming milestones, underscoring another year of successful growth and development as a US owned and operated battery cell manufacturer.

Building Better Batteries

Tesla Battery Day – EnPower’s Take

Authors: Adrian Yao, CTO & Dee Strand, VP Engineering

On September 22, 2020, Tesla hosted their first Battery Day event during which they shared plans to scale Lithium-ion (Li-ion) manufacturing output to 3 TWh/year and halve the cost of battery packs. At EnPower, we are excited about the implications for the Li-ion industry, the future of electric mobility, and the meaningful anthropogenic greenhouse gas emission reductions that will result from mass adoption of EVs.

In our view, Tesla Battery Day validates EnPower’s approach to solving the most formidable challenges in energy storage. We are encouraged by the complementary nature of EnPower’s first-principles approach to re-engineering the Li-ion cell and Tesla’s rethinking of end-to-end efficiencies in TWh-manufacturing. Overall, our key takeaways are:

- Li-ion will be the technology to dominate until at least mid-century

- EnPower technology is highly complementary to Tesla’s new cell design

- There is no silver bullet or magic molecule in the battery industry

- Dry electrode processing may be part of the cost reduction strategy, but it is not near-term

- Cost is critical, but $/kWh is not the only metric

We appreciate Tesla’s vision and endless energy to push other industry players to innovate faster and we look forward to commercializing technologies to accelerate our transition to electric mobility and sustainable storage.

Li-ion is here to stay…

At a time when solid state batteries are taking center stage in research communities, venture capital, and Wall Street, Tesla’s lack of comment on either the timing or feasibility of solid state batteries for the automotive market seemed intentional. We interpret it as a signal by today’s most successful electric vehicle company that the readiness level of solid state technology for EV applications is low. Conversely, according to Tesla, the Li-ion Gigafactories currently under construction worldwide are soon to evolve into Terafactories, solidly securing Li-ion’s position as the dominant energy storage technology until at least mid-century.

Tesla’s announcement dovetails with EnPower’s strategy and core technology focus on Li-ion electrode architectures. Applying elegant, engineering-based innovations to structures, EnPower enables significantly improved power performance upon charge and discharge, while preserving high energy densities in Li-ion cells. These performance improvements are accomplished while ensuring the architectures can be manufactured in scalable fashion with processes that are truly drop-in compatible with existing manufacturing infrastructure. By utilizing existing, proven Li-ion materials and requiring little to no re-tooling, EnPower achieves performance improvements with comparable unit economics to traditional electrodes. We are pleased to share this outlook with Tesla. The market opportunity for Li-ion remains tremendous with explosive growth potential in the near-term.

Potential synergies with the 4680

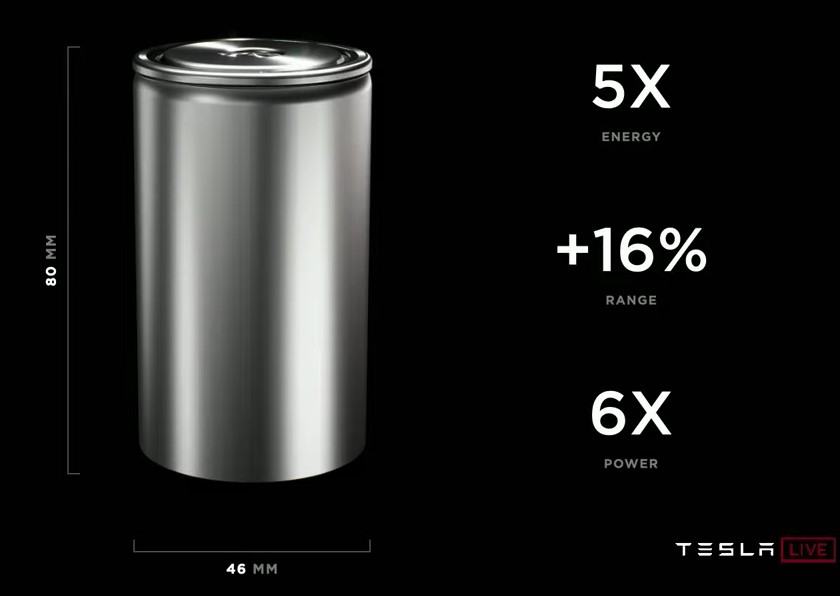

The new 4680 cell form factor (Figure 1), enabled by a “tabless” electrode design, was one of the key cell engineering innovations Tesla shared. The following claims were made regarding the new cell form factor:

- 5X energy

- +16% driving range

- 6X power

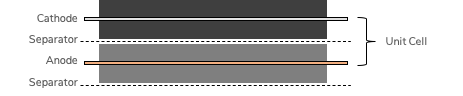

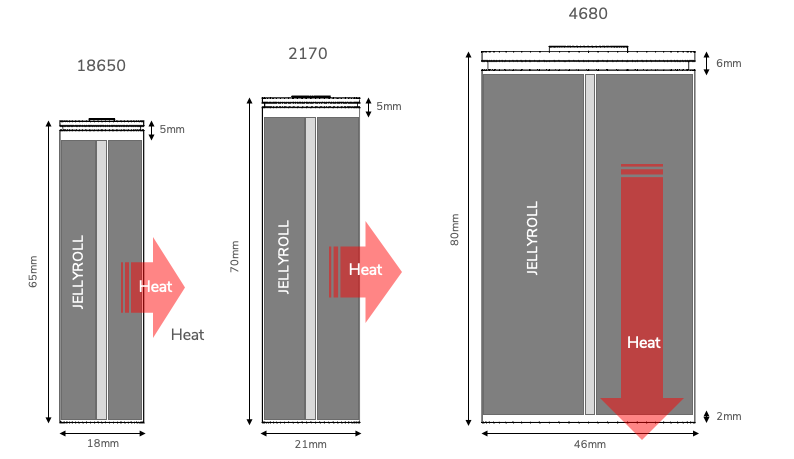

Presumably, this is compared to the recently pioneered 2170 cylindrical cell form factor used in the Tesla Model 3 and Model Y, which was Tesla’s first increased cell size from the original 18650s used in the Tesla Model S and Roadster. Merely increasing the cell sizes will undoubtedly yield total energy content gains, but doing so does not necessarily result in energy density gains. While there is reduced inactive mass in a larger cell due to reduced overall packaging, the cell energy densities are primarily dictated by their unit-cell designs (Figure 2)—i.e. the design of the individual anode, separator, and cathode layers comprising the electrochemical cell. In cylindrical cells, a cathode tape and an anode tape are sandwiched between two separator films and are wound together in a jellyroll before insertion into a metal can. When the same unit-cell design is scaled from an 18650 to a 2170, each tape’s thickness remains constant while their lengths and widths will increase to accommodate the taller can and larger diameter. Scaling a unit-cell designed for “high energy” (e.g. one with thick anodes and cathodes) from an 18650 to a 2170 yields a ~49% increase in energy content but only a ~2% increase in energy density [1]. These numbers appear to correlate with Tesla’s claims of a 50% increase in energy comparing their 2170 with their previous 18650 format.

Returning to the 4680, assuming the electrode’s unit-cell design does not change, the cell energy of the new 4680 can be estimated to be roughly ~4.6x times the 2170 (Figure 3) using a simple cylindrical volume estimate. Given that the jellyroll space utilization inside the can will be more efficient with a “tabless” electrode design, it appears the stated 5x higher energy comes almost entirely from the cell form factor. Unit-cell designs, and therefore energy densities, are then likely to remain close to the current ~265 Wh/kg specific and ~730 Wh/L volumetric, but we cannot be certain until the full specs are released. The improved driving range of +16% likely comes from the increased packing efficiency of fewer, larger cylindrical cells in an overall pack. In moving from 18650s to 2170s, ~33% fewer cells were required to maintain the same energy content1. A similar benefit is expected here.

Typically, larger cylindrical cells are plagued by poor heat dissipation at the cylinder core, and therefore have not been as prevalent as the smaller formats popularized by consumer electronics. Tesla’s proposed “tabless” electrode designs (although, given the design, maybe one should actually refer to these as “infinitely tabbed”) seek to address this thermal challenge by heat sinking through the copper and aluminum current collectors axially to the bottom of the cell can (Figure 3), enabling substantially more uniform temperature profiles within the cell and efficient bottom-side cooling in a battery pack (similar to the Rivian design). While this type of tabless principle in cylindrical cells is not novel, it is new for GWh- and TWh-implementation. The inability to Supercharge without causing dangerous thermal buildup was the key challenge driving Tesla towards the “tabless” design. However, addressing this heat-sinking challenge does not improve fast-charging capabilities—rather, it only addresses the handicap of a 4680 form factor to allow the same unit-cell designs to charge at the same rate as they otherwise could if assembled into smaller cylindrical cells or pouch cell formats, which are much more efficient in heat-dissipation. A nominal 5x increase in energy content (Wh) should also enable a minimum baseline of 5x increase in power output (W). As the heat-sinking capability in 4680s likely outperform even the smaller 2170s, the stated 6x improvement in power likely only correlates to a ~20% increase in rate capability prior to exceeding a temperature threshold.

Reducing resistance (impedance) is key to enabling higher performance (e.g. faster charging) cells, but it is important to note that the total impedance in any Li-ion cell is comprised of many contributing factors, namely electronic and ionic. Both electrons and ions need to move for an electrochemical cell to function, and because ions are orders of magnitude larger than electrons, they move more slowly. Therefore, the electronic resistance from metallic current collectors addressed by the “tabless” electrode design is typically not a limitation. Conversely, the energy-to-power tradeoff and limitations inhibiting extreme fast charging (XFC) are primarily due to the ions’ inability to move quickly through unit-cell structures. This is the key problem addressed by EnPower’s technology.

If EnPower’s advanced electrode architectures are implemented into Tesla’s 4680s, ionic “mass transport” will be dramatically improved while efficient heat sinking and low electrical resistance will contribute further to performance. Putting these two technologies together will therefore ultimately increase Supercharging speeds for the benefit of consumer experience.

No silver bullet, no magic molecule

Many expected Tesla to announce a “battery breakthrough” that would change the paradigm altogether. Instead, Tesla announced a portfolio of incremental improvements that add up to significant cost reductions. While some believe Tesla Battery Day did not “live up to the hype”, this comes as no surprise to us. Batteries are challenging, and there is no silver bullet or magic molecule that will single-handedly change the game. This is evident not only in the electrochemistry but also apparent at a much more macroscopic perspective, where there is no agreement on one battery design. Instead, Tesla is adopting a three-pronged “diversified approach” to serve various consumer needs by using entirely different batteries: (1) lithium iron-phosphate (LFP) prismatic cell-to-pack designs for low-cost, long-cycle life vehicles, (2) NMC-based cylindrical Li-ion for medium tier / luxury sedans, and (3) high-Nickel 4680s for long-range vehicles. It must be understood that there is no one-size-fits-all approach to solving this industry’s challenges.

EnPower is focusing on form factor- and (generally) chemistry-agnostic improvements to the fundamental unit-cell architectures that inherently enhance performance in all Li-ion batteries. Looking through the “first-principles” lens, there is no reason battery electrodes should look the way they do today—homogeneous—when their behavior is inherently non-uniform. Intentionally engineered heterogeneity is the crux of EnPower’s approach, and we have figured out how to do this at scale in our own pilot line with industry-standard equipment. We can apply this approach to engineer faster-charging anodes for LFP-based cells (as their reduced range likely requires more frequent fast-charging), higher power-to-energy ratios in “standard” Li-ion cells, and enable longer cycle life by structuring high-Nickel content cathode materials strategically. When an EV-ready silicon anode material matures, developed by either Tesla or other industry players like Sila Nanotechnologies, they can be incorporated into EnPower’s architectures for yet further performance improvements.

Dry electrode processing is not easy, but when the time comes it can benefit from EnPower architectures

One key announcement made at Tesla Battery Day is the dry electrode processing technology originally acquired from Maxwell. The impetus is to circumvent the industry-standard solvent-based approach to manufacturing electrodes and instead produce films directly from dry powder. This has the potential to dramatically reduce costs, but as industry experts seem to agree, this is very difficult. While it may appear to be a straightforward concept and purely a process-engineering hurdle, it is laden with very complex materials science challenges that have yet to be solved. This includes the development of completely new binders (possibly Teflon-based), complex powder surface treatments, active material optimization, and more. Once these fundamental (electro)chemistry challenges have been solved, only then can process engineering ensue to outcompete today’s GWh-scale manufacturing (where electrode production is not a bottleneck), followed by cell optimization to ensure fast-charge and cycle life performance are at least on-par with today’s state-of-art. For someone who often makes bold claims, Elon Musk was visibly hesitant on the technology readiness. Our guess is that dry processed electrodes will not find their way into your Tesla within this decade.

Regardless, electrodes manufactured via wet or dry processes will still abide by the same laws of physics, and the aforementioned unit-cell mass-transport limitations still apply. So long as the electrolyte system is liquid-phase (i.e. not solid-state), our advanced electrode architectures will remain relevant even as manufacturing approaches evolve.

Important considerations outside of cost

The key focus of Tesla Battery Day was on cell cost for good reasons. The Li-ion battery still represents a disproportionate component cost to EVs today, and $/kWh must come down further to enable true mass adoption. However, we believe a myopic focus on $/kWh alone, either by lowering manufacturing costs or increasing energy density, limits performance innovation. Today, the top concern limiting EV adoption that is second only to cost is the inability to fast-charge. This is true for the 40% of Americans that do not own a garage to charge overnight, or for the much greater population in Europe and China that will inevitably rely upon public fast-charging infrastructure. Range is no longer the key concern, as is evident by even Tesla’s incorporation of low-range LFP cells into EVs for the Chinese market. And since fast-charging is often directly at odds with cycle life due to accelerated aging phenomena, the OEM’s costs (via warranties) due to battery pack replacements could be substantial, reflecting an increase in lifetime $/kWh to increase.

For these reasons, EnPower’s focus is to enable Li-ion batteries capable of extreme fast charge (0-80% SOC in 15-minutes) without compromising cycle life or increasing costs. While there are improvements to be made on charging protocols, thermal management, vehicle pack architectures, and high power charging infrastructure, fast-charging in high energy density cells is fundamentally a unit-cell architecture physics problem and will not be possible without rethinking their design. At EnPower, we have already demonstrated significant improvements over conventionally designed Li-ion cells in projects with major automotive OEMs and look forward to working with more partners to bring our technology to market.

Closing thoughts…

Overall, we found Tesla’s Battery Day to be an important spotlight on this generation-defining energy challenge, as we need the brightest minds in the world to accelerate the adoption of clean, sustainable energy technologies. We also need to move faster than ever before, and an industry “level-set” on the scales required to achieve complete electrification was much needed. Irrespective of how the markets evaluate whether Tesla hit their mark, we are grateful for their continued push to advance the world toward a more sustainable electric future. We look forward to the future of electric mobility.

[1] Jason B. Quinn et al 2018 J. Electrochem. Soc. 165 A3284

The Underserved Battery Markets

Batteries aren’t just for EVs. There is a world of opportunity; many will prove vital to the green world economy that lies ahead.

Arizona Business Leaders Call for Federal Investments in Clean Energy and Jobs to Grow Arizona’s Economy

Arizona business leaders come together for a live video press conference to speak on their support of the Build Back Better Act

Footer

ABOUT US

HEADQUARTERS