EnPower, Inc. is celebrating National Battery Day by showcasing the company's significant upcoming milestones, underscoring another year of successful growth and development as a US owned and operated battery cell manufacturer.

Building Better Batteries

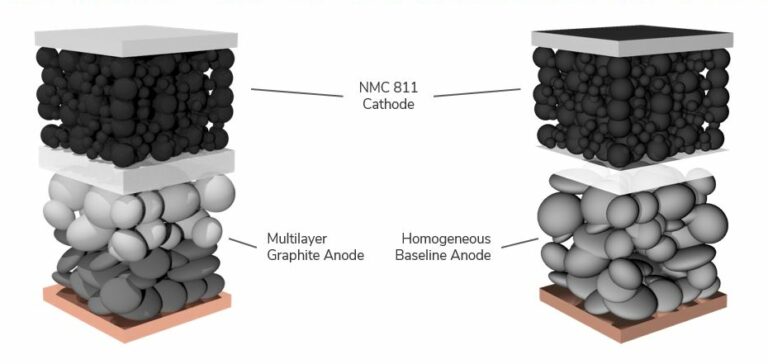

Comparing EnPower’s Multilayer Electrodes to a Homogeneous Baseline

November 18, 2021

Electrode design plays a critical role in defining the power and energy performance of Li-ion cells. Today’s state-of-art electrodes are manufactured by mixing active material particles, typically ranging from hundreds of nanometers to tens of micrometers, with binders, conductive aids, and solvents to form a slurry, then coating that slurry onto a metallic current collector foil as a wet film. After drying, the result is an electrode that consists of a single, homogeneous layer of material. In thick electrodes, the long, tortuous path that ions must travel into and out of the electrode results in sluggish lithium-ion flow. Thus, as electrode thickness is increased to achieve higher energy density, discharge power performance and charge rate suffer.

EnPower is developing advanced multilayer electrode architectures to address this underlying problem of lithium-ion mass transport. Instead of depositing a single wet film coating onto a foil substrate, EnPower simultaneously coats multiple slurries onto the foil, one on top of the other. The result is an electrode design that breaks away from the traditional energy-power tradeoff, enabling repeated fast charging and greater power performance for high energy density cells, or an increase in energy density given a specific power requirement. Multilayer design strategies can be applied to both the anode and cathode to improve specific performance parameters. Here, we look at the benefits of multilayer anodes, which are currently being sampled for customer validation.

To measure the benefit of multilayer anode architectures, we compare their performance with “homogeneous baselines.” A homogeneous baseline is created by blending the formulations of each individual layer in a multilayer anode together to create a homogeneous slurry with the same net mass fractions of active materials, binders, and conductive aids as the multilayer electrode. This homogeneous slurry is then coated onto the metallic current collector foil as a single layer, typical of conventional Li-ion cells.

MULTILAYER ANODES

VS.

HOMOGENEOUS BASELINE

Multilayer anodes vs. homogeneous baseline

Multilayer and homogeneous baseline anodes are chemically identical and have identical thicknesses. The only difference between them is the engineered architecture imposed on the multilayer version. When multilayer anodes and their homogeneous baselines are paired with the same electrolyte, separator, and cathode, assembled into the same cell design, and tested under the same conditions, any difference in performance can then be attributed solely to the engineered mesoscale architecture.

Ultimately, the performance of a cell depends on many factors in addition to electrode design, such as constituent materials, electrolyte additives, and cell design. While EnPower’s development samples are not optimized cell systems, they serve to prove the performance delta between multilayer electrode designs and conventional designs. As EnPower scales production, these demonstrated performance benefits will translate to optimized cells that outperform cells with conventional electrodes.

Test for Yourself

EnPower is currently sampling 4.2 and 6.5 Ah stacked pouch cells with multilayer and homogeneous baseline anodes. Sampling both types of cells enables an “apples-to-apples” comparison of discharge rate capability and fast charge performance when tested with your specific protocol and test regimes.

Interested in sampling our cells?

Test for Yourself

EnPower is currently sampling 4.2 and 6.5 Ah stacked pouch cells with multilayer and homogeneous baseline anodes. Sampling both types of cells enables an “apples-to-apples” comparison of discharge rate capability and fast charge performance when tested with your specific protocol and test regimes.

Interested in sampling our cells?

Learn More

High energy density cells with EnPower’s patented multilayer anodes demonstrate superior fast charge cycle life, reduced DC internal resistance (DCIR), improved discharge performance, and improved discharge capacity retention when compared to the same cell designs with conventional electrode architectures. Review test results from EnPower comparing multilayer anodes with their homogeneous baselines in our most recent Technical Papers.

White Paper

Learn more about the benefits of EnPower’s multilayer electrodes, including superior fast-charge cycle life, reduced DC internal resistance (DCIR), and improved discharge performance for high-energy cells.

Technical Note

Review the data that shows EnPower’s Multilayer anodes improving discharge capacity retention by 30-40% across three energy density regimes.

The Underserved Battery Markets

Batteries aren’t just for EVs. There is a world of opportunity; many will prove vital to the green world economy that lies ahead.

Unlocking the Future of High Performance Electric Transportation

EnPower's advancements in Lithium-ion batteries are enabling the electrification of high performance vehicles, electric aviation, and eVTOL.

Footer

ABOUT US

HEADQUARTERS